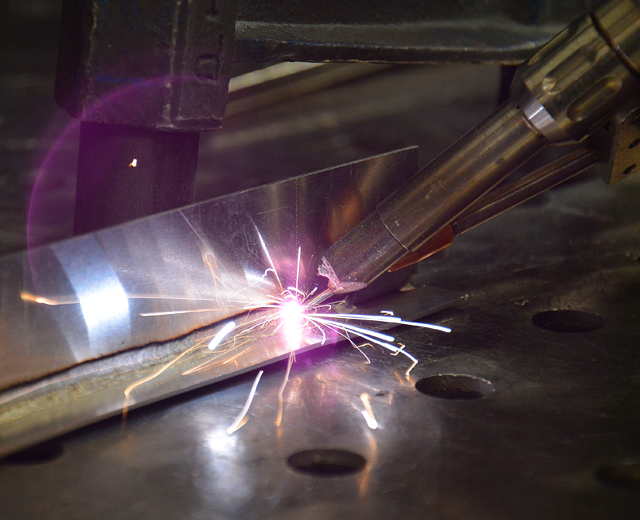

Laser Welding

At Gala Gar we bet

for safe laser welding

Our GLS 1500 equipment along with the recommended accessories and special booths manufactured in-house will provide you with a clean, fast and safe welding experience.

What can laser welding provide?

More productivity

– Fast welding speed

– Reduced heat affected zone

– Reduced deformation

– No limit to the number of materials to be welded

– Higher work quality

– Narrower beads

– Unskilled labor.

What do you need for laser welding?

Preventive security

– Safe equipment for the user

– Laser zone enabled as secure

– Training in the use of the equipment

– Creation of a security plan

GLS 1500: for welding and cutting.

Includes:

– Equipment with transport trolley

– Winder

– Laser Gun

– 8 m fiber optic cable.

– Chilly refrigeration unit

– Coolant.

– Gas flow protection system

– Set of different nozzles

– Safety clamp.

Accessories

homologated

Glasses

High quality laser welding goggles for laser welding protection certified for GLS 1500 – D-LB60D8

Servore V2

Electronic shield for UV protectionfor additional use in addition to the approved goggles.

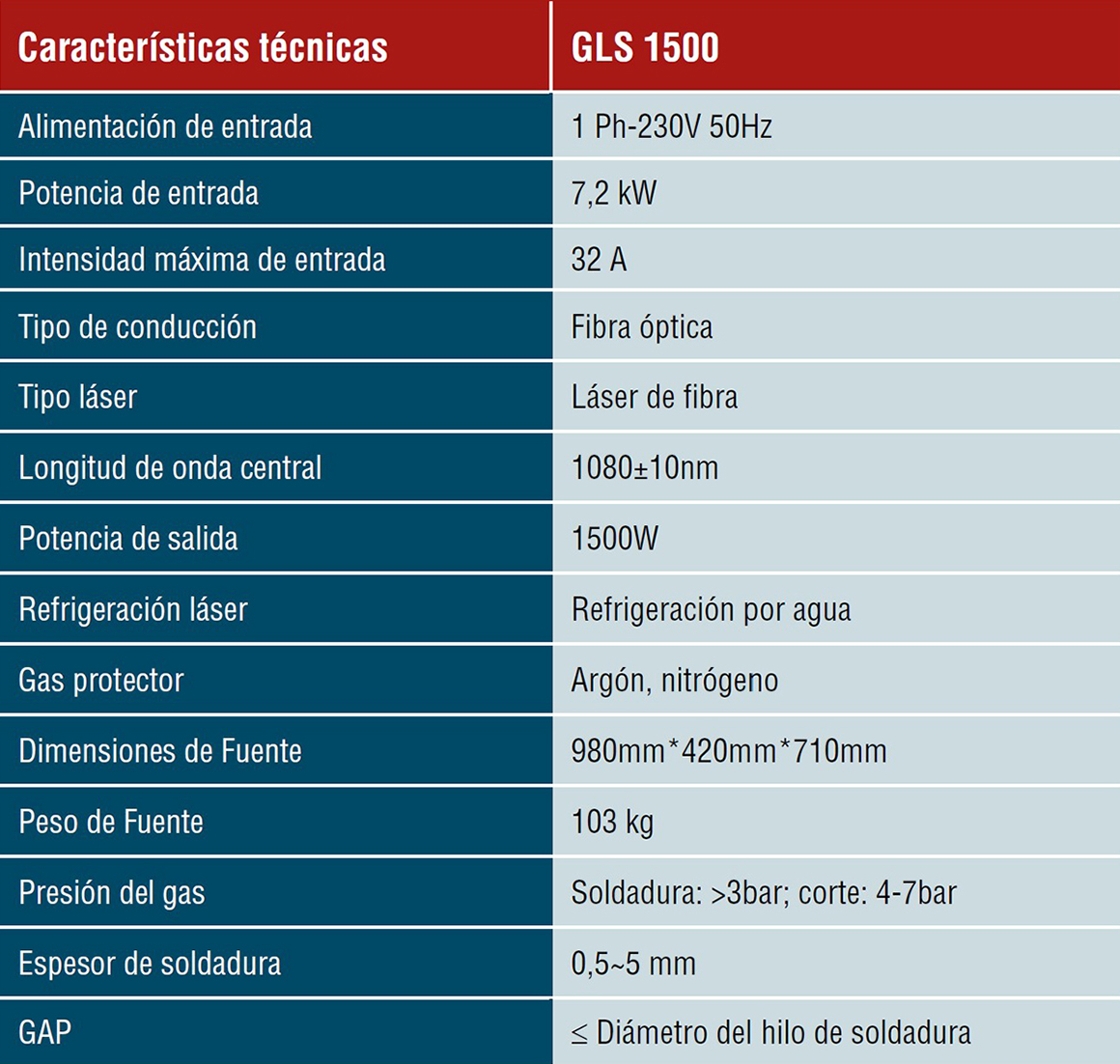

Data sheet GLS 1500

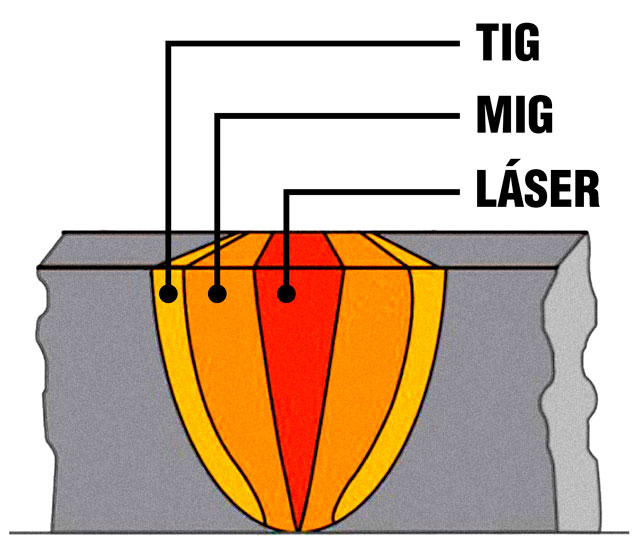

Process comparison table

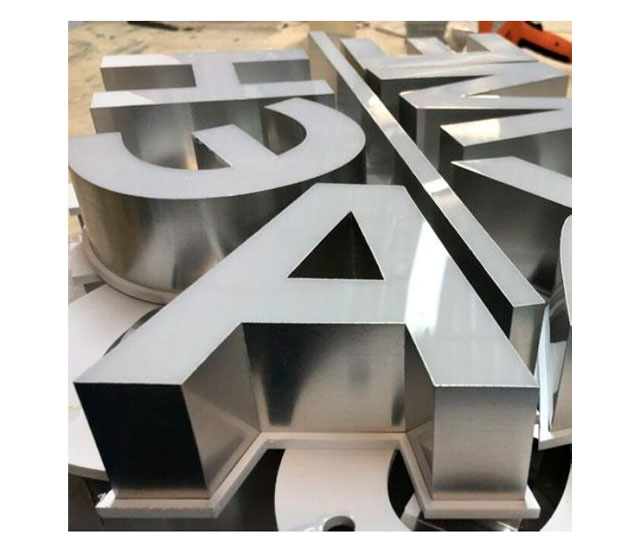

Applications

Our recommendations

Booths

Creation of a safe area for equipment use

The GLS 1500 welding unit for class 4 laser welding generates a radiation process in which operators must be protected from direct radiation and diffuse radiation within a radius of action of more than 100 m.

In order to isolate operators outside the manual welding area from this radiation, it is necessary to create a laser safety area that complies with the aforementioned standards.

Characteristics:

- Area 4×3 meters.

- Double sliding door 1+1 meters,

- Safety locking system.

- Opening and safety pushbutton panel.

- Signaling beacon for access.

- Closed-circuit video.

- Interior lighting.

- Access control from inside.

- Safety cabinet, machine connection.

- Turnkey product.

- Installation and start-up included.

Closed standard conformation. Modular system adaptable to customer needs.

It may be necessary to incorporate a roof. Customer location will be studied.

Standard options available

Standard closed

Contact us for special sizes and spaces.

Standard options available

Wall cabin

Standard options available

Corner booth

Tables with fume extraction

With the laser system there is a danger of smoke inhalation in which the operator must be protected.

These fumes are more concentrated than in normal welding.

Fumes derived from the welding, cutting and cleaning process must be collected and filtered by a specific system for this purpose, being necessary autonomous systems in confined areas.

It is recommended that the fume aspiration system aspirate laterally or at the bottom. Do not face upward to prevent particles from entering the laser torch lens.

Some samples of laser cords

Steel

Some samples of laser cords

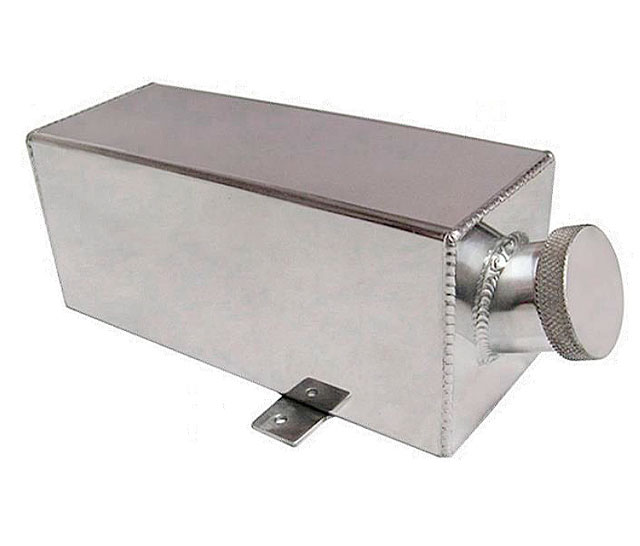

Aluminum

Some samples of laser cords

Galvanized

Publications about laser welding in our RRSS

Issues to consider:

Galagar Newsletter

Subscribe now!

You will receive information about news, offers and discounts for our products.