Still not working with laser welding?

If not, you are losing productive efficiency.

- Up to 10 times faster than TIG.

- Clean finishes, without rework or splashes.

- No deformations: minimal thermally affected zone.

- Compatible with: inox, aluminum, titanium, copper and more.

- Operation with unqualified personnel.

- Sustainable technology, environmentally friendly technology.

- Safe: Complies with RD 486/2010 and UNE EN 60825-1 standard.

Laser welding

GLS1500 / 2000

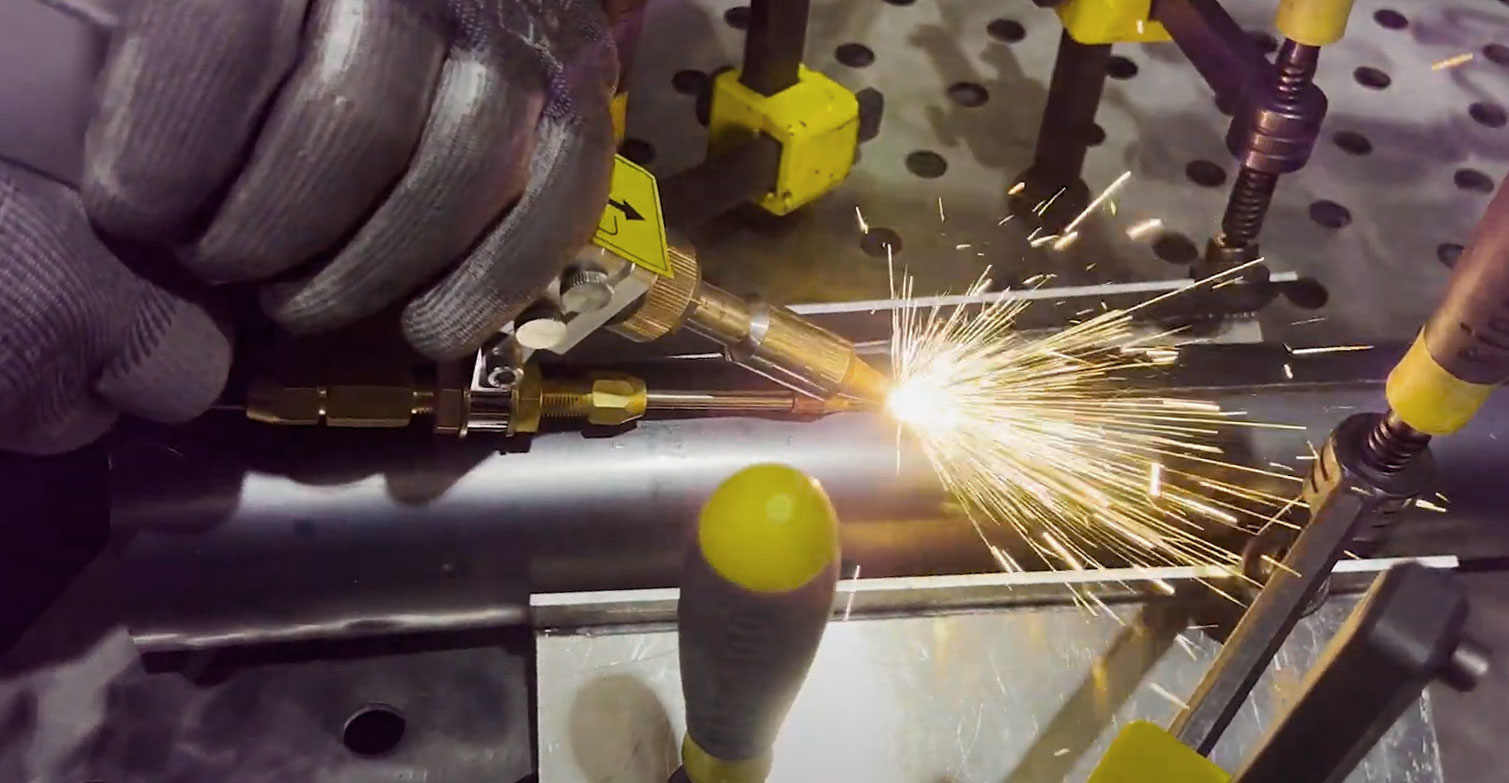

Gala Gar’s new GLS 1500 and 2000 W manual laser welding equipment marks a turning point in the production model of today’s industry.

This technology makes it possible to achieve an end product of excellent quality, increase the speed of speed production speed and significantly reduce operating costs.

In addition, its intuitive operation makes it easy to use even without previous welding experience.

In short, a more efficient solution, safer and more sustainable than traditional welding methods.

Highest quality

Raise the quality standard of your products

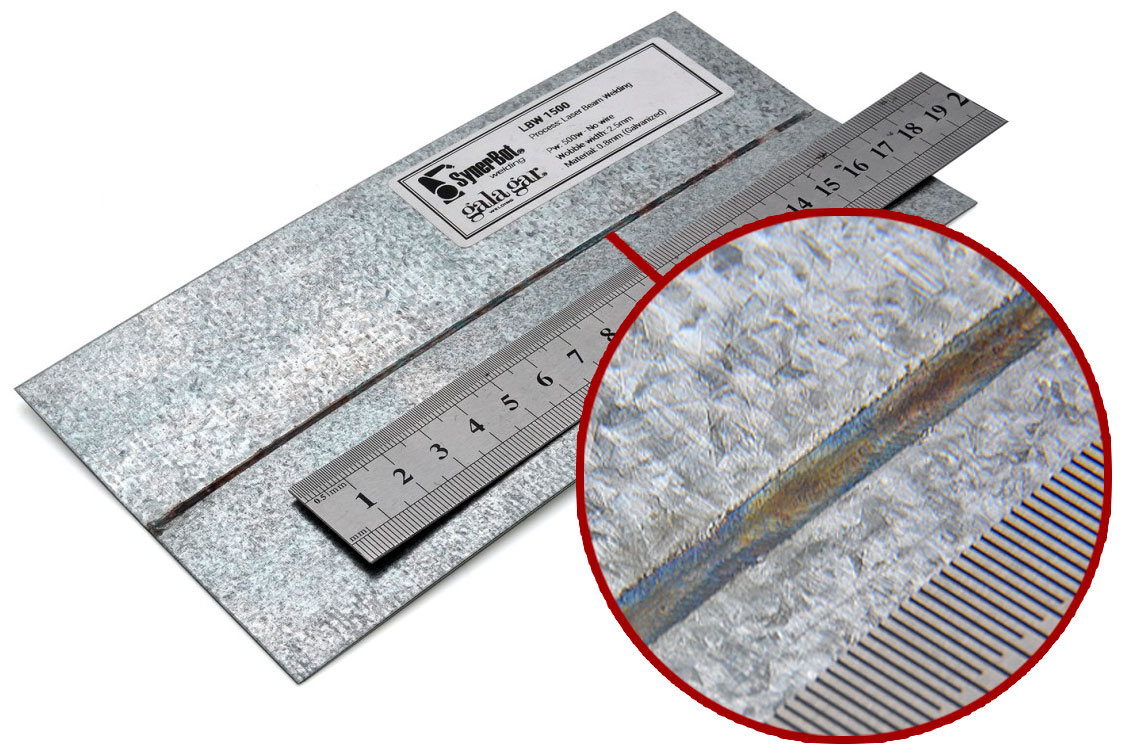

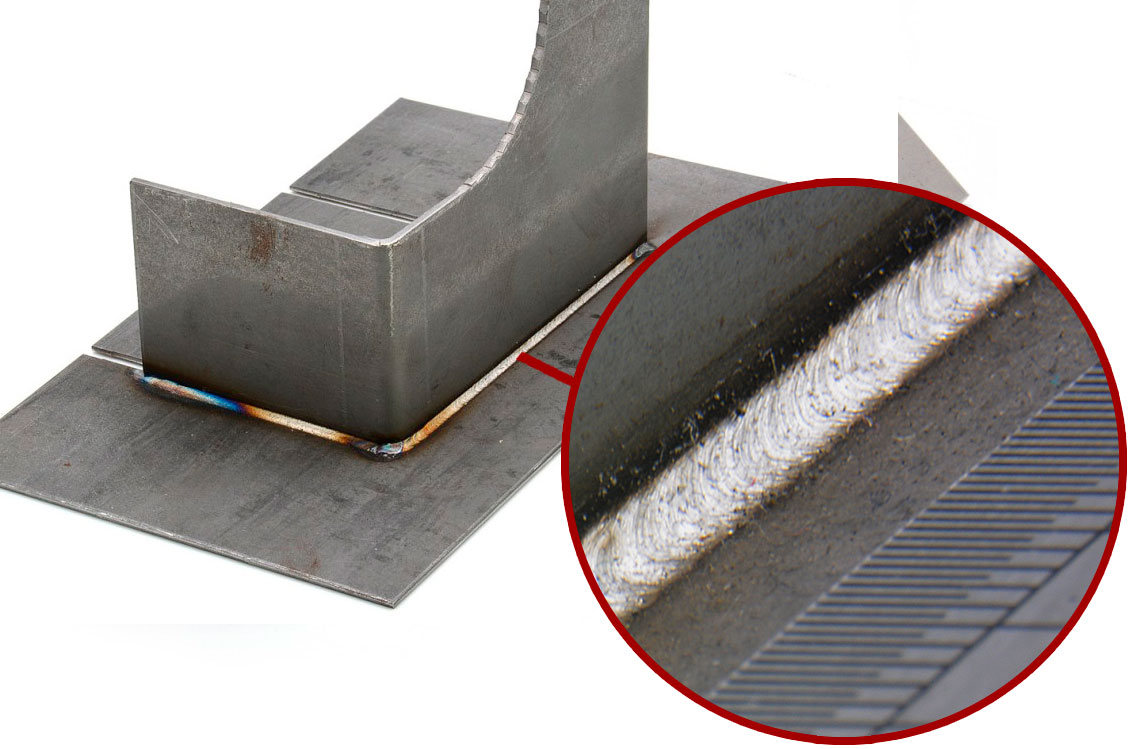

Narrower cords, no need for reworking.

High quality, repeatable finished product.

Laser welding is a revolutionary technique that guarantees perfect and homogeneous finishes, eliminating the need for subsequent reworking or rework.

All this speeds up the production process, optimizes work times and translates into greater operational efficiency, significant cost savings and higher profitability for your business.

Raise the production standard with a clean, precise and flawless weld.

100% Multipurpose

Capaz of trabaj twith anymaterial

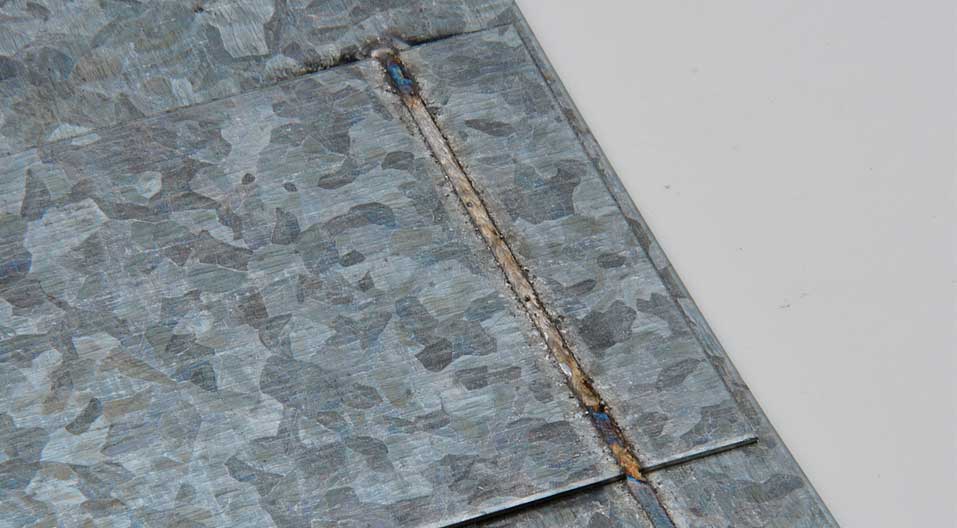

Unmatched finishes on any type of support: galvanized, aluminum, steel…

Its quick nozzle change allows working in multiple scenarios: flat, right angles, sharp edges, curves, etc.

Ease of use

Intuitive operation

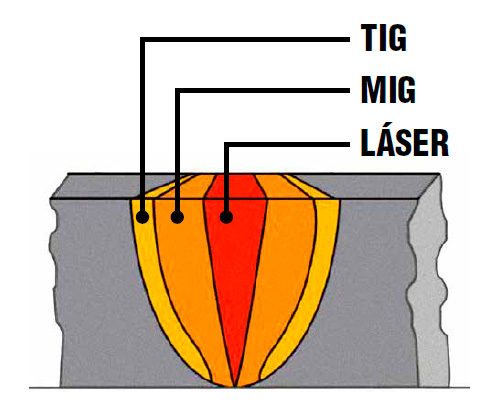

Laser welding is an intuitive and fast solution that requires no previous welding experience. Unlike techniques such as TIG or MIG, it can be operated by unqualified personnel, provided that the indicated safety measures are followed.

Easy to use from day one, ideal for maximizing the efficiency of your process without complications.

Minimal impact,

Maximumresistance

Example of laser welding engraved at actual speed.

Up to 10 times faster than TIG.

Up to 4 times faster than MIG.

Less heat affected zone,

deformations are reduced.

Mechanical properties of the part maintained. Mlower porosity, less cracking, higher bond strength.

Your safety,

isourtop priority

Our GLS 1500 and 2000 class 4 laser welding equipment complies with the Royal Decree 299/2016 and the standards UNE-EN 60825-1 y 60825-4guaranteeing maximum safety for the operator and the environment.

Also available with approved enclosure with anti-radiation shielding, access control, signage, and turnkey commissioning.

Certified equipment and PPE: laser specific goggles, shields, clothing and gloves.

Protect your team,

work without risk

We take care of your safety and that of your equipment.

Learn about the technology from our experts:

Sustainable technology,

environmentally friendly

In addition, laser technology is cleaner and more sustainable: it generates less waste, reduces polluting emissions and consumes less energy. Its high precision minimizes material waste, contributing to more environmentally responsible manufacturing processes.

What do our customers think?

Boilermaking and Transformed Products – San Adrian

Javier Ciordia – Welding Manager

“With this technology you don’t need to be an expert to get a good finish on the parts. The quality has nothing to do with the MAG and TIG welding we worked with before, in fact we have certified this type of laser welding by sending it to a laboratory and the results are that it has the same strength even with fewer throats.”

Megablok – Zaragoza

Enrique Villaverde – CEO

“Until now, we used the wire or spot welding system in our production line. With the new laser welding system we have incorporated, we can make our products with much better quality and faster.”

Metalwork Gajón – Zaragoza

Daniel Gajón – CEO

“For us, implementing laser welding equipment in our production system has meant a significant improvement, reducing manufacturing times and quality in our final product. Undoubtedly, a great success”.